A162 ENDURANCE GRADE HEAVY DUTY SINGLE ACTING ROD SEAL

- EXCEPTIONAL HIGH SEALING PERFORMANCE EVEN LOW PRESSURES

- SUITABLE FOR HIGH PRESSURE AND SHOCK LOADS

- INCREASED SEAL STABILITY

- LOWER FRICTION AND DRY ROD SEALING PERFORMANCE

- HAS EXTRUSION PROTECTION RING

- EASY INSTALLATION

- VERY ECONOMIC

- DESIGNED FOR HEAVY DUTY APPLICATIONS

Technical Properties

|

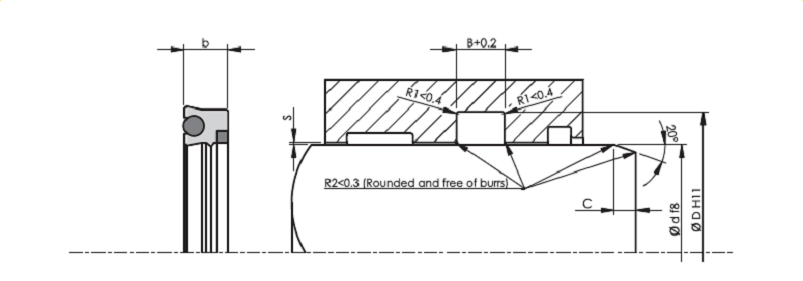

A162 ENDURANCE GRADE PU HEAVY DUTY SINGLE ACTING ROD SEAL ALP A162 U Ring has symmetrical lips, energising O Ring, POM extrusion ring and is designed to be used for heavy duty hydraulic cylinders and rod applications. A162 heavy duty PU rod seals are manufactured with 95 shore special endurance grade ALP PU compound, NBR O Ring and Polyacetal extrusion ring as standard and could be manufactured in FKM (VITON) for extreme temperature conditions on your demand. Please contact our sales team for pricing and lead time. A162 heavy duty rod seal offers exceptional high performance under high pressure working conditions and shock loads. The twin lip design offers lower friction dry rod sealing and increased seal stability, with a wide range of metric and imperial dimensions available exstock. A162 ROD SEALS to be used safely for construction machinery, moving and loading platforms, forklifts, agricultural machinery, injection moulding machinery, mining and steel industry, and any heavy working condition cylinders etc. A162 heavy duty PU U seal is recommend to be used with min one ALP guidening element combination such as A251, A254, A255, A256, depending on the working conditions. Please do not hesitate to send us an email if you have any queries This email address is being protected from spambots. You need JavaScript enabled to view it. …

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||