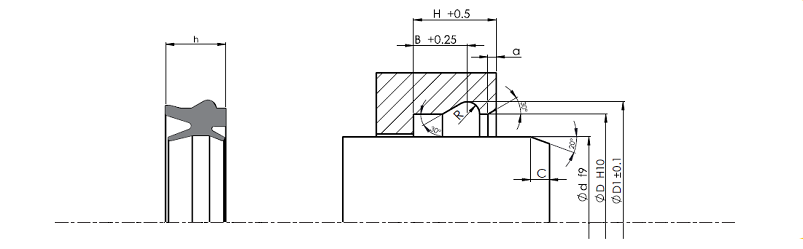

A852 SINGLE ACTING COMBINED PNEUMATIC ROD AND WIPER SEAL

- PROVIDES EXCELLENT SEALING PERFORMANCE

- FUNCTIONS AS ROD SEAL AND WIPER AT THE SAME TIME

- SUITABLE FOR OILED OR OIL-FREE WORKING CONDITIONS

- EASY INSTALLATION TO OPEN HOUSINGS

- VERY SMOOTH WORKING PERFORMANCE DUE TO LIP GEOMETRY

- HIGH WEAR RESISTANCE

- RESISTANCE TO HARSH WORKING CONDITIONS

- LONG SERVICE LIFE

- VERY ECONOMIC

- WIDE RANGE DIMENSIONS AVAILABLE

Technical Properties

|

A852 SINGLE ACTING PNEUMATIC ROD AND WIPER SEAL ALP A852 pneumatic combined rod seal / wiper is designed especially to be used with pneumatic cylinders for rod applications and performs sealing, wiping and fixings functions whilst working in the cylinder. A852 single acting pneumatic rod seal is manufactured with high specification special 92 shore ALP PU compound as standard and could be manufactured with ALP FKM compound for extreme working conditions on your demand. Please contact our sales team for pricing and lead time, This email address is being protected from spambots. You need JavaScript enabled to view it.. Wide range of sizes available on Exstock. ALP A852 pneumatic rod seal functions as a sealing element and wiper at the same time with excellent sealing performance even in very small assembly conditions. It also offers high wear resistance, long service life, easy installation, resistance to very harsh working conditions because of its robust profile design, very low dynamic and static friction and smooth running due to lip geometry and is suitable for oiled or oil-free working conditions (note that the seal should be lubricated on assembly). A852 single acting combined pneumatic rod seal / wiper is to be used safely for pneumatic cylinders. |

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||