A109 DOUBLE ACTING HEAVY DUTY PISTON SEAL SET

- STICK SLEEP FREE

- 700 BAR WORKING PERFORMANCE

- ONE SEAL ONE PISTON COMPLETE SEALING SOLUTION

- HIGH ABRASION RESISTANCE

- EXCELLENT SEALING PERFORMANCE UNDER SHOCK LOADS AND VIBRATIONS

- LONG SERVICE LIFE

- VERY ECONOMIC

Technical Properties

|

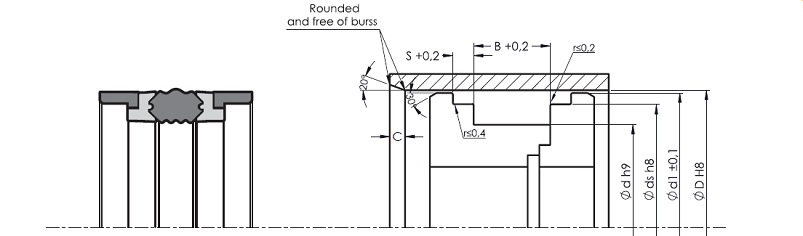

A109 HEAVY DUTY DOUBLE ACTING COMPACT PISTON SEAL SET A109 compact piston seal is designed to be used for heavy duty hydraulic cylinders and piston applications. A109 heavy duty five piece piston seal is manufactured one 80 shore multiple lip NBR sealing ring, two TPE backup rings and two POM guide rings as standard seal kit. A109 double acting heavy duty piston seal offers excellent sealing performance between 0-700 BAR pressure and shock loads and vibration conditions. It offers a complete sealing solution with very economical sealing and guidening, very easy snap installation because of split design for TPE backup rings and POM guide rings, and one seal could solve one heavy duty piston sealing. Wide range of metric and imperial dimensions available on Exstock A109 compact piston seal set is to be used safely for forklift trucks, heavy duty injection machinery, heavy duty construction machinery, cranes, marine industry, mining machinery, loading platforms and any heavy duty cylinders. A109 piston seal can be manufactured with FKM sealing element and PTFE guide rings for extreme temperature condition cylinders if it is required. Please do not hesitate to send us an email if you have any queries This email address is being protected from spambots. You need JavaScript enabled to view it. … |

|||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||